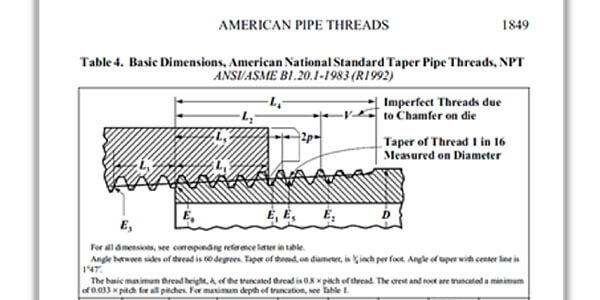

Pipe Thread / NPT (Taper) is the American standard thread pattern for pipe connections and has been in use in the U.S. since the mid 1800’s. NPT threads are cut at cut at an angle of about 60° along the length of the fitting, and the actual individual threads are cut at an angle of about 1° 47’ from the centerline of the fitting. As a male and female NPT fitting are tightened against this taper the connection is increasingly tight. However because of allowances and variations in the precise thread cuts it’s necessary to use a sealant such as Teflon tape or pipe thread sealant to assure a leak-free connection.

Compression fittings are common, but their threads don’t match with any other thread type. This fitting received its name because the thread is compressed the pipe tube inserted into it to seal it. Compression fittings have straight threads and are made of brass or plastic and are often used on soft copper pipe and small-diameter tubing. The angle stop under your sink is one example of compression threads. A compression fitting includes an outer compression nut and an inner compression ring or ferrule (sometimes call the sleeve). A flare fitting is a type of compression fitting used with metal tubing, usually soft steel or soft copper or aluminum.

Similarities – Threaded and compression fittings both use threads to help make their connections. However, they use the threads differently.

Differences – Threaded fittings have a 1-piece connection end that is used to connect to port/block. These threads create the seal for the connection with the support of Teflon tape or pipe dope and are manufactured in a tapered, cone-shape. Whereas compression fittings have a 3-piece connection that is tasked with its connection to tubes. Compression ends typically are a parallel shape and instead of sealing on the threads, the seal point is created with the assistance of a ferrule (ring, olive or sleeve) and a compression nut. So in this case, the threads simply needed to hold the fitting together with the compression nut.